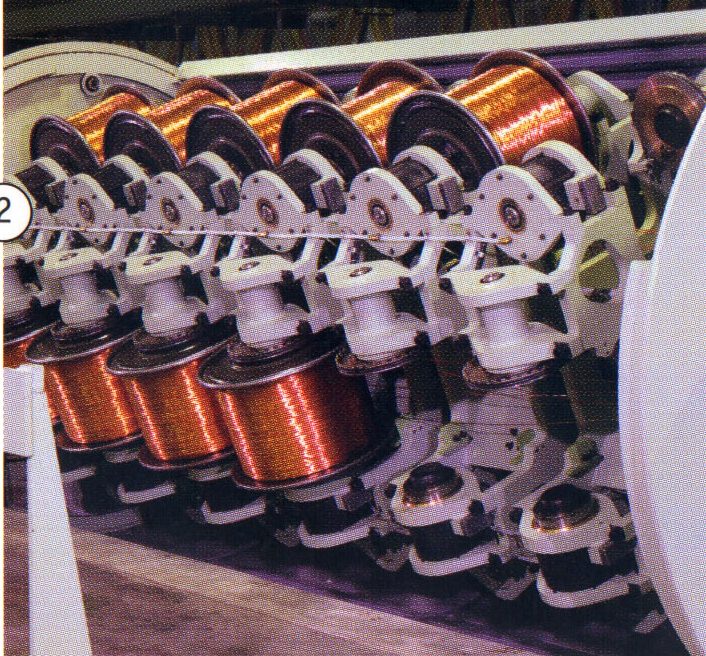

RIGID Frame and Planetary machines are two of our specialties, we have developed algorithms and controls for smooth tension payoff controls. Don’t believe all the hype about how to do it cheap or expensive. There is only one proven way. Basically Recipe driven the operator enters his footage for the input wire and the machine does the rest. On this type of retrofit we also incorporate a broken wire scheme that has been proven for the past 20+ years. On a complete retro fit we can do away with clunky back breaking gear’s and have input pitch selection that is touchscreen controlled.

Robotic loaders for stranders are also electrically automated so that the hardware is more current, there is no need for limit switches that breakdown and that need repairing. Proximity sensors that count pulses are all that is needed.

We have tried the “measure” and adjust approach for tension control, after you spend $100K you end up with a mediocre system that kind of works. As for measuring with light beams through a machine for broken wires it might work on 7 bobbin machine but when it comes to 61 bobbin that’s a different story. Our hardware is industrial grade and is over the counter hardware not proprietary to your vendor.

We have 30+ years in electronic line shafting experience, we have worked with various different manufacturers of electronic line shafting controls. On medium voltage power cables its not really required as the pitch control is so tight that you cannot measure the difference. We have seen a lot of mis-applications of Electronic Line shafting. There is only one instance where this type of line shafting is required for the most part its not needed.

Please contact myself (Rick Nieuwenhuysen) for a more candid discussion.