Celebrating 28 years of Wire and Cable Machine Control Expertise

This November mark’s the start of Rewire Automation Inc. 18th year of Business It also markes the 28th year of my involvement in the wire and cable business. Back in 1990 I started with Ceeco Machinery and worked extensively in the field for 10 years. In October of 2000 i resigned and started Rewire Automation Inc.

In 2016 we ended up in Marshall, Texas working on a old Bartell Coiler we updated this Coiler economically and is currently in production. The usage of Allen Bradley 750 Series Drives became a new standard in this industry. The advantages were huge in any drive system, provided the performance was included in the better costing AC Flux Vector Drives. over the next two years I would be commissioning over Seventy (70) AB 755 drives. This speaks volumes in this business as Parker was the only drive capable of any performance.

In 2016 we ended up in Marshall, Texas working on a old Bartell Coiler we updated this Coiler economically and is currently in production. The usage of Allen Bradley 750 Series Drives became a new standard in this industry. The advantages were huge in any drive system, provided the performance was included in the better costing AC Flux Vector Drives. over the next two years I would be commissioning over Seventy (70) AB 755 drives. This speaks volumes in this business as Parker was the only drive capable of any performance.

I also traveled to Brazil in 2016 for Phelps Dodge / General Cables, we upgraded two Rigid Frame with infinite Tension control. This process is done with Festo Muscles and lots of Mathematics, in the end the operator enters the copper weight and or length and the starting tension he so desires and the machine auto-depletes the wire tension as the diameter is reduced. This has been installed on 14 stranders to date.

I also traveled to Brazil in 2016 for Phelps Dodge / General Cables, we upgraded two Rigid Frame with infinite Tension control. This process is done with Festo Muscles and lots of Mathematics, in the end the operator enters the copper weight and or length and the starting tension he so desires and the machine auto-depletes the wire tension as the diameter is reduced. This has been installed on 14 stranders to date.

I then ended up in Turkey to visit a machine builder Kabmak, my travelling companion said “as good as Ceeco if not better”. To this statement I h ave to agree. It was a wonderful experience and a surprise to see our planetary machine turning in Turkey. This was a quick fact finding trip aimed at seeing if there were going to be issues before shipping to the US. We found several important issues that would be rectified before shipping.

ave to agree. It was a wonderful experience and a surprise to see our planetary machine turning in Turkey. This was a quick fact finding trip aimed at seeing if there were going to be issues before shipping to the US. We found several important issues that would be rectified before shipping.

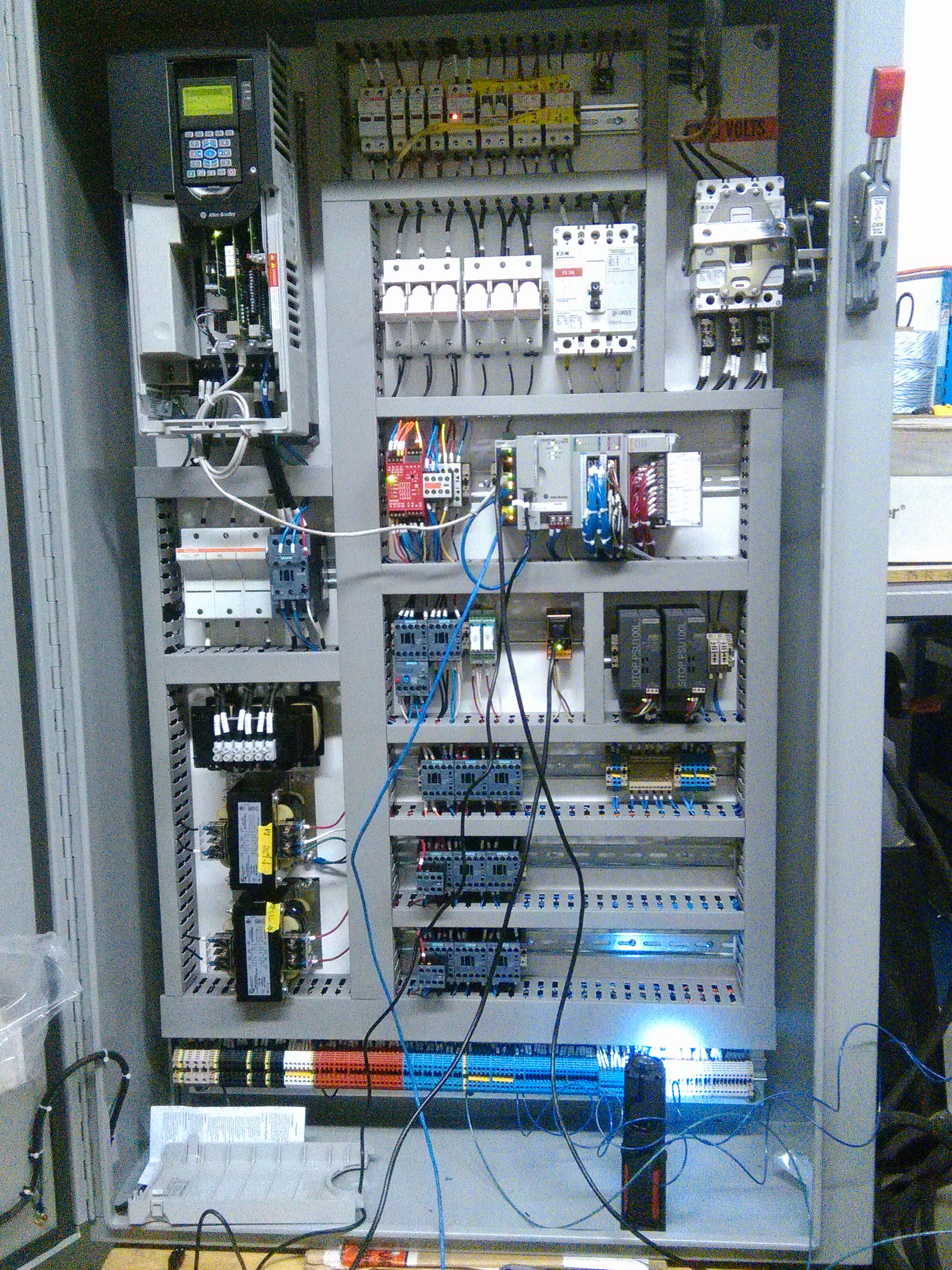

In the end of 2016 we were commissioned to build a 300 HP drive system for a rod breakdown machine. This involved a drive that weighed inat a whopping 327 pounds, at this HP I could have used the AB drives  but my customer requested that we use Parker. No problem as we use both. After the drive and machine installation the owner was able to compact his 3/8 aluminium rod at the speed he needs.

but my customer requested that we use Parker. No problem as we use both. After the drive and machine installation the owner was able to compact his 3/8 aluminium rod at the speed he needs.

In 2016 / 2017 we engaged with a German machine builder and commissioned new cable stranders. Working for a German Premier  Machine builder that appreciates quality, integrity and customer service. The service we provide gives the customer immediate North American service if necessary or a voice to talk to on this side of the Atlantic. We are very happy with this arrangement and we hope to continue working with our over seas colleagues. Please keep selling Stephan M. !!

Machine builder that appreciates quality, integrity and customer service. The service we provide gives the customer immediate North American service if necessary or a voice to talk to on this side of the Atlantic. We are very happy with this arrangement and we hope to continue working with our over seas colleagues. Please keep selling Stephan M. !!

In February of 2017 we were asked to build 3 control systems for 3  armoring lines and we were also asked to quote and delivering drive controls for a new dual head extrusion line (THHN). After considering all the options we delivered a quote that was accepted and delivered the controls to our client. The 3 armoring controls are commissioned and currently in production and we are currently in the final debugging phase of the new extrusion line, this should be completed before Christmas, and I will have more on this later.

armoring lines and we were also asked to quote and delivering drive controls for a new dual head extrusion line (THHN). After considering all the options we delivered a quote that was accepted and delivered the controls to our client. The 3 armoring controls are commissioned and currently in production and we are currently in the final debugging phase of the new extrusion line, this should be completed before Christmas, and I will have more on this later.

Now where does it go from here ??

Fast forward 18 years later Rewire is still in Business and will continue to do so for as long as the phone keeps ringing.

Rewire has continued to forge ahead and stay at the foreground of technology