Spring is here and the Far east winds are streaming in my hair.

In April I will attend The 2015 Atlanta Wire show, this event is held every two years and I will have seen a lot of familiar faces. Hopefully I will have another chance to meet and discuss opportunities with people whom are looking for solutions and answers to technical matters. Time is still flying in the Wire industry. Interwire is held at the Georgia Congress center in Atlanta, Georgia.

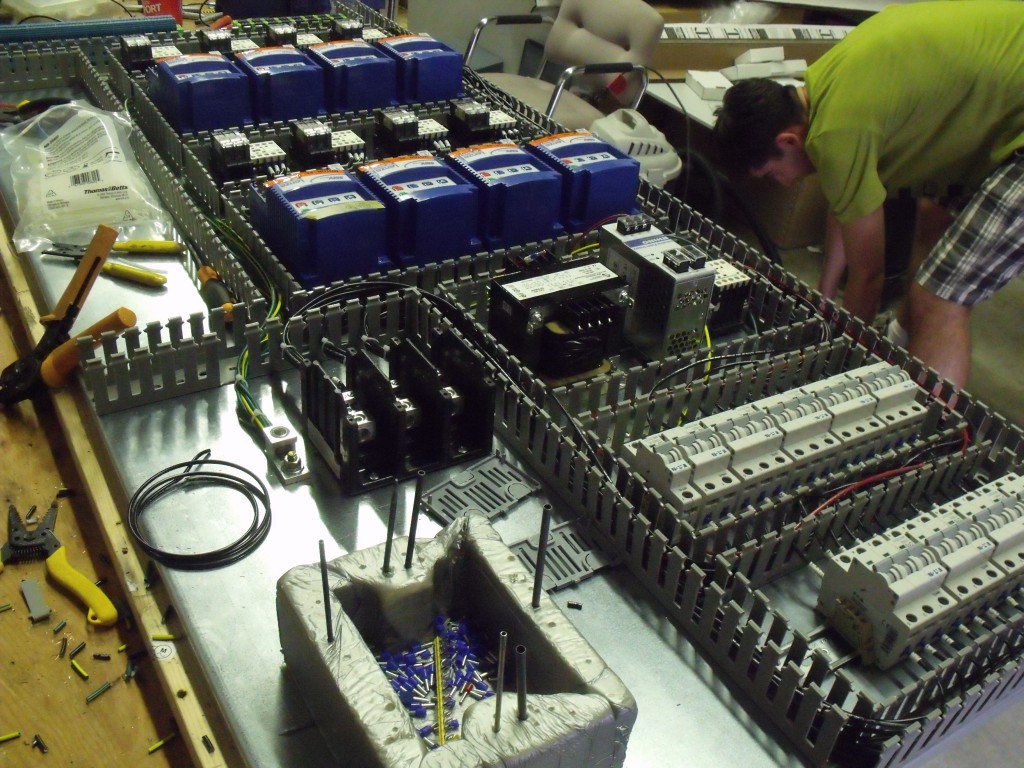

During 2014 we had an opportunity to work on a variety of companies one of which was the Toronto Star. We were asked to replace an older Reliance drive system on a Harris NP630 Inserter. We looked a Siemens option that basically changes out the drive only. This method keeps the older field wiring att ached to two 1KVA transformers and we surmised we could do better. Starting with a blank sheet of paper we designed a control system that basically replaces the existing back plane with a new one. Instead of Heavy transformers and variable field resistors we opted for a safe electronic option. We also used Emerson Mentor MP Drives and Field Regulators. The controls are clean and safe and installation was a days work. Afterwards the Star ordered several more for replacing the remaining Inserter controls. If you have a Harris NP630 inserter that has the oldReliance MaxPack drive call us for a solution you may be surprised at how cost effective a new panel board is.

ached to two 1KVA transformers and we surmised we could do better. Starting with a blank sheet of paper we designed a control system that basically replaces the existing back plane with a new one. Instead of Heavy transformers and variable field resistors we opted for a safe electronic option. We also used Emerson Mentor MP Drives and Field Regulators. The controls are clean and safe and installation was a days work. Afterwards the Star ordered several more for replacing the remaining Inserter controls. If you have a Harris NP630 inserter that has the oldReliance MaxPack drive call us for a solution you may be surprised at how cost effective a new panel board is.

In January 2014 another customer of ours wanted a couple of control systems built so we created a video of the process thought we would share it with you, the first is for 14 drive monitor door cut-outs that monitor each drive.

The second video is for the assembly of the backplane for the same machine.

The end user was Cenovus and we basically provided the drive control panels.

In May / June, 2014 we were asked by well known equipment manufacturer to build 4 control enclosures to house 26 drives for a European customer and 27 single (individual drive controls) for Southwire we jumped at the chance. The client supplied us with the LENZE drives and we supplied the design and controls. We worked to make the deadline delivery and stayed on budget. After we shipped the equipment we received 90 % of the amount owing to us and we owed the customer 3 days of commissioning in the Carolina’s. After a week the customer informed us he was ready for us to start commissioning. On arrival nothing was built the machinery was some welded frames and I was very disappointed with this client. He then proceeded to tell me I was in charge for building the machines and that I should not worry about finances as he has it all un

In May / June, 2014 we were asked by well known equipment manufacturer to build 4 control enclosures to house 26 drives for a European customer and 27 single (individual drive controls) for Southwire we jumped at the chance. The client supplied us with the LENZE drives and we supplied the design and controls. We worked to make the deadline delivery and stayed on budget. After we shipped the equipment we received 90 % of the amount owing to us and we owed the customer 3 days of commissioning in the Carolina’s. After a week the customer informed us he was ready for us to start commissioning. On arrival nothing was built the machinery was some welded frames and I was very disappointed with this client. He then proceeded to tell me I was in charge for building the machines and that I should not worry about finances as he has it all un der control. After working for a month it soon became apparent that this clients holidays were more important to him than the needs of his customer. This so called intelligent human being shipped the machinery incomplete to Austria where he paid another crew of people to finish the machine. After several months of haggling he paid Rewire the final 10% and stiffed our company for about $ 6000 Canadian. He then proceeded to send us an invoice in the first week April 2015 for $ 7000 stating the machine was not manufactured to European CE standards. When the welds were breaking off the machine and the $ 9.00 distance sensors were moving from right to left I noted that the produced machine was basically junk. The moral of the story, don’t trust anyone that states ” money is not your problem” in the end it will be.

der control. After working for a month it soon became apparent that this clients holidays were more important to him than the needs of his customer. This so called intelligent human being shipped the machinery incomplete to Austria where he paid another crew of people to finish the machine. After several months of haggling he paid Rewire the final 10% and stiffed our company for about $ 6000 Canadian. He then proceeded to send us an invoice in the first week April 2015 for $ 7000 stating the machine was not manufactured to European CE standards. When the welds were breaking off the machine and the $ 9.00 distance sensors were moving from right to left I noted that the produced machine was basically junk. The moral of the story, don’t trust anyone that states ” money is not your problem” in the end it will be.

In September of 2014 we had the opportunity to remove an Extrusion line from a Alcan facility in Quebec. This Extrusion line had two large accumulators mounted near the ceiling. Working with Gordon Infanti from GP Future Tech and his crew we managed to remove the extrusion equipment (the whole line) in about 8 days. We shipped 7 tractor trailers in 5 days. All equipment arrived in Missouri unscathed and under budget. Technically this was not to difficult to work on, it was physically demanding and we worked long hours, after we were done the customer was happy we were efficient and dedicated workers, again zero time lost due to accidents and having the right crew in place made all the difference.

Eurotherm LINK1 and LINK2 phase-out

Eurotherm LINK1 and LINK2 fiber optic controls are now being replaced by Ether-LINK nice but not really useful when your 620 LINK Drive hardware is obsolete. As Parker – Eurotherm are no longer producing 620 Drives or LINK-2 Fiber Optic Hardware we have basically created a document that explains an alternative to LINK-2 Hardware. Rewire Automation Inc. has been removing LINK-2 controls from existing control systems for the past 2 years. Typically we will replace the LINK-2 drive module with an 6055 ENET ETHERNET drive module. An Allen Bradley Controllogix PLC and a small 6″ Allen Bradley Touchscreen replaces the LINK-2 Touchscreen. The Allen Bradley processor can be programmed with Controllogix Lite, the touchscreen software is Free. And the drive can communicate nicely utilizing Allen Bradley Ethernet I/P protocol. If you are running older Ceeco / Nextrom 4″ Armoring lines that have LINK fiber optic drives and hardware you may want to think on a long range replacement strategy, please give us a call to show you what we can do for you. Same great Parker 690 Drive with alternative way of control.

Omron / Lenze Ethernet I/P

During 2014 we were asked to develop a control algorithm that would keep a drive on in case the Ethernet wiring was disrupted. Using the Lenze SMV drive With a CJ Omron processor we developed an control scheme that would allow the drive to continue to run in the unlikely event that the ethernet communication stopped functioning. This ment that the customer had full network control of the drive and the system would revert to manual control in the likely event that the Communication went down.This solution maybe helpful if you would like to pull data from the drive and garantee that the drive never shuts off due to communication error.