So here we are in uncharted territory, 20 years ago we started Rewire Automation Inc. Our history is deeply entrenched in the Wire and Cable Industry. We have manufactured control upgrades for Armoring, Stranders, Twisters / Bunchers, Extrusion and Wire Drawing. Last month we just completed another Double Twist Strander retrofit.

CEECO 150 RPM 1250 TRUNION TAKEUP LG S.KOREA 1996

Summer of 2019

300 HP DC Motor 500 VDC Syncro Drawbench with Dual Spooler

Over the summer of 2019 Rewire Automation worked on a Syncro Wire drawing machine. This unit was controlled by an obscure operating system and required a more robust control system. As multiple attempts had been made in the past the plan was never implemented. We offered a controls package that would allow the cost to be reduced if the customer supplied the installation manpower. The customer would be responsible for wiring changes etc. Rewire Automation would design and program the Machine. Through dialog we co-ordinated the installation and on arrival we worked out multiple algorithms for the Takeup. After two weeks of programming the machine was ready to go back Safely into production. As this system retained the existing speed control we installed the logic for safe and reliable reel transference, including Loading and Unloading.

Spring of 2019 we received a purchase order from GP Future Tech for a 1 250 Double Twist Strander. We started with Engineering a new set of Drawings and to engineering a solution for the clients machine. In our quote we offered an AC 100 HP Drive upgrade complete with new pintle motors. and operator controls. This system also reduced the main wiring to AC voltages only as the controls are wireless WiFi.

250 Double Twist Strander. We started with Engineering a new set of Drawings and to engineering a solution for the clients machine. In our quote we offered an AC 100 HP Drive upgrade complete with new pintle motors. and operator controls. This system also reduced the main wiring to AC voltages only as the controls are wireless WiFi.

This project was completed in 3 weeks. This included a Slip Ring rewiring, Cradle rebuild and Brand New Baldor/ Reliance Motor(s).

We also built a 50 HP Concentric Neutral Control Panel for a Canadian company. This Control panel was delivered in September of 2019. Once the machine is installed we will be offering our commissioning services.

We also built a 50 HP Concentric Neutral Control Panel for a Canadian company. This Control panel was delivered in September of 2019. Once the machine is installed we will be offering our commissioning services.

ABB ACS880

In December / January 2019 we worked worked on replacing four capstan drives for a CV line. The existing DC drives were of 25 year old vintage. We spent a considerable amount of time on the replacement drives that were ABB ACS880 drives. The drive Ethernet communication was tested and re-tested. Eventually we created some Ad-On

instructions into the Allen Bradley processor Since we had a large number of drives that would be replaced in the coming shut-downs.

Controller to Drive UDT

The drives we were replacing were Parker SSD 590 LINK DC drives. Technically the control is within the LINK program the drive is only tagged to follow instructions. So we utilized drive PID’s and started the line back up. After two weeks of scheduled downtime the line was returned to cable producing operation.

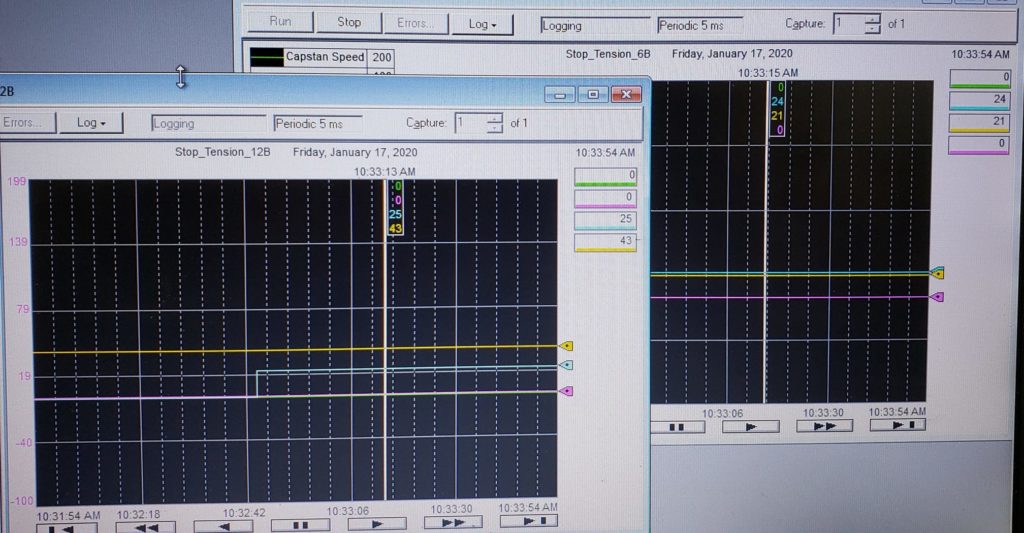

In January 2020 we worked on a SKET Concentric Strander in South Carolina.

Troubleshooting with Trending

This machine is complete in Allen Bradley with Parker 590 + Drives. I spent a week determining what brake does what, and what machine sequence is correct and why someone had changed the Control Pressure Settings. On completion we stood confidently beside the machine and proved that stop was possible without breaking any wires.